Dürr and GROB unveil energy-efficient concept factory for lithium-ion battery cell production

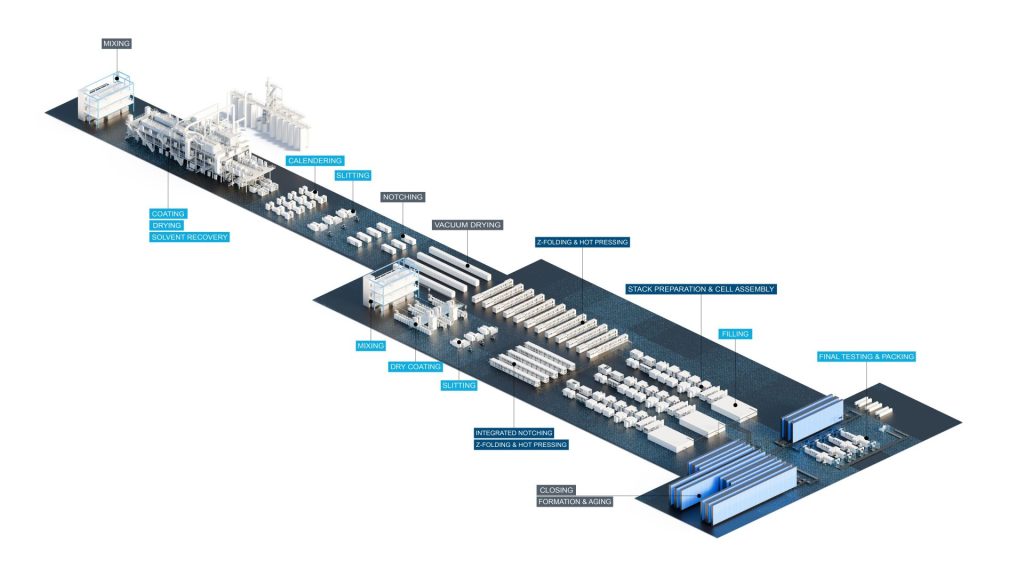

Dürr and GROB have introduced a new concept factory for lithium-ion battery cell production aimed at reducing energy and space requirements while improving overall efficiency. The two companies presented the concept at The Battery Show India 2025 in Greater Noida, highlighting key technologies such as dry electrode coating and Z-folder technology for cell assembly with integrated notching.

Dürr and GROB have been collaborating since 2022 in the field of lithium-ion battery production technology. Their goal is to establish themselves as system suppliers for battery manufacturing equipment in Europe, North America, and India. The companies plan to localise technology and work with Indian battery manufacturers to support the development of a self-reliant domestic battery ecosystem under the ‘Atmanirbhar Bharat’ initiative.

The new concept factory integrates dry coating and Z-folder technology. Compared to conventional setups, the process reportedly reduces space requirements by about 50 percent and energy consumption by 70 percent, contributing to lower operational costs.

Dry coating process:

Dürr’s dry coating system, X.Cellify DC, uses the “Activated Dry Electrode®” process developed with LiCAP Technologies. The system employs a dry-mixed active material pressed into a free-standing film and laminated onto the collector foil. This eliminates the drying and solvent recovery steps typical of wet coating, reducing energy and space use. Excess film material can be reused in production. Dürr recently demonstrated proof of concept for this process and is seeking pilot partners to scale it for industrial use.

Cell assembly and electrolyte filling

GROB’s new generation of Z-folders combines notching and folding within one system, aiming for higher throughput and compact operation. The design features controlled separator guidance and electrode magazine buffering, targeting 95 percent system availability.

Dürr has developed a single-step electrolyte filling process operating at up to 30 bar, which is two to three times higher than standard industry pressure levels. This approach allows precise dosing and reduces the time required for electrolyte penetration into the cell material.

Digitalization and process control

Both companies are integrating end-to-end digitalisation through virtual simulation and process mapping. A digital twin enables pre-production testing and optimization, while Dürr’s iTAC MES/MOM software manages production steps, traceability, and quality analysis to improve equipment effectiveness.

Wet coating and related systems

In addition to dry coating, Dürr continues to offer wet coating systems under its X.Cellify SC range. These systems allow simultaneous two-sided coating and drying with an air flotation dryer. Dürr also provides solvent recovery, distillation, and calendering systems designed for energy efficiency and emission reduction. Its condenser and concentrator systems can achieve solvent emission levels below 1 mg NMP/Nm³.

Dürr’s calendering machines feature “Dynamic Gap Control,” using sensors to maintain consistent layer thickness during electrode densification.

Dürr and GROB are showcasing the concept factory and related technologies at Booth B344 during The Battery Show India 2025, being held from October 30 to November 1 at the India Expo Mart & Centre, Greater Noida.

Dürr is also introducing a unified naming convention for its products under the brand “X.Cellify,” covering electrode coating and electrolyte filling systems.

According to Aji Philip, Head of LiB at Dürr India, “We are driving India’s clean mobility transition with world-class manufacturing systems for lithium-ion batteries that combine international engineering excellence with local manufacturing and service throughout the entire project and product life cycle.”

GROB Group CEO German Wankmiller said, “With our expanded portfolio of highly available machines and systems, we jointly cover almost the entire value chain for battery cell production with our own technologies.”

Also read: Facilitating sustainable electrode production for Lithium-ion cells

Subscribe & Stay Informed

Subscribe today for free and stay on top of latest developments in EV domain.