Ceramion⁺™ solid-state lithium metal battery technology: Vision for safer, denser and indigenous energy storage

Inventus Battery Energy Technologies, led by Founder & CEO Dr S.R.S. Prabaharan, is developing a Lithium Metal All-Solid-State Battery (LM-ASSB) platform based on its Ceramion⁺™ solid electrolyte technology. In this interview, Dr Prabaharan outlines the core aspects of the technology, key performance parameters, technical challenges addressed, and the roadmap toward commercial readiness. The discussion also covers potential application segments, localisation considerations, and strategies for manufacturing scale-up and market deployment.

Could you explain the core battery technology your team is developing?

Inventus is developing India’s first Lithium Metal All-Solid-State Battery (LM-ASSB) platform powered by our proprietary Ceramion⁺™ solid electrolyte—a flexible ceramic oxide that enables high-performance, intrinsically safe energy storage. Unlike conventional lithium-ion batteries that rely on flammable liquid electrolytes, Ceramion⁺™ eliminates leakage and dendrite risks by forming a stable interface with lithium metal anodes.

Through interface engineering and surface coatings, we optimized charge transfer reactions, enabling high-voltage cathodes such as NMC811 (up to 4.45 V) and LNMO (up to 4.8V) to operate efficiently with lithium metal.

Our ASSB cells deliver:

- High Ionic Conductivity: Ceramion⁺™ achieves >4 mS/cm at room temperature, rivalling liquid electrolytes while maintaining the safety and stability of a solid-state system.

- High Energy Density: Our pouch cells deliver ~350 Wh/kg at the cell level, enabled by lithium metal anodes, thin solid electrolyte layers, and high-voltage cathodes.

- Zero Liquid Electrolyte: By eliminating flammable liquid electrolytes, Ceramion⁺™ removes risks of leakage, fire, and dendrite growth—ensuring intrinsic safety.

- Wide Operating Range: Stable performance from -20°C to +70°C makes these cells suitable for diverse environments, from defence and aerospace to EVs in hot climates.

- Ultra-Thin Stack Design: Inventus’s pouch packs are engineered at just 8 mm thickness, with scalable form factors that support modular integration across applications.

- Intrinsic Safety: Proven resilience under extreme abuse: no fire or rupture even at 180°C heat, nail penetration, or external short circuit conditions.

- Fast Charging Capability: Ceramion⁺™ enables rapid charging, reaching 80% state of charge in under 15 minutes at a 5C rate—critical for EV adoption.

- High-voltage tolerance: Up to 4.45 V charging to reap the maximum advantage of our MO-coated proprietary NMC811 CAM.

These specifications firmly position Inventus as a global differentiator—bringing together superionic conductivity, exceptional energy density, and intrinsic safety within a manufacturable, flexible solid-state platform (first of its kind in the world).

This technology is modular, scalable, and compatible with high-voltage cathodes such as LNMO, NMC90, and NMC811, making it ideal for next-generation EVs, aerospace, and defence applications.

Why is Ceramion⁺™ unique?

1. Ceramic Backbone (Oxide Solid Electrolyte)

- The core of Ceramion⁺™ is a ceramic oxide solid electrolyte powder engineered for superionic conductivity at room temperature and thermal stability up to 800°C.

- This ceramic phase provides the ionic transport pathways and the intrinsic safety (non-flammable, thermally robust).

- We use a proprietary mechanical stabilizer, imparting flexibility to Ceramic powder solid electrolyte without compromising ionic conductivity.

- This allows the electrolyte to be processed into thin membranes that can withstand roll-to-roll calendaring and lamination.

2. Dry Processing Route

- Unlike wet slurry ceramic casting (which introduces solvents and drying steps), Inventus uses a dry processing method.

- This ensures ambient manufacturability, reduced contamination risk, and compatibility with roll-to-roll scale-up.

What are the most significant technical challenges you have addressed so far in advancing this battery chemistry?

Developing a commercially viable Lithium Metal All-Solid-State Battery (LM-ASSB) is one of the most demanding frontiers in energy storage. At Inventus, our journey with Ceramion⁺™ required solving several deep-material and interface challenges that have historically limited solid-state adoption.

- Suppressing Dendrites: Lithium dendrite growth is the single greatest safety risk in solid-state batteries. Ceramion⁺™ forms a dense, fast ion-conductive flexible matrix (>4 mS/cm at room temperature) that resists dendrite penetration without the need for external stack pressure. This breakthrough ensures both safety and long cycle life.

- Reducing Interfacial Resistance: Solid-state interfaces often suffer from high resistance, slowing charge transfer. By engineering grain boundary pathways and optimizing stack pressure through pouch cell design, we achieved very low interfacial resistance, enabling efficient charge/discharge kinetics even at high current densities.

- Moisture Tolerance: Conventional ceramic electrolytes are highly sensitive to ambient moisture, complicating processing and storage. Our ceramic oxide matrix resists hydrolysis, allowing ambient processing and extending shelf life. This makes Ceramion⁺™ practical for industrial-scale roll-to-roll manufacturing.

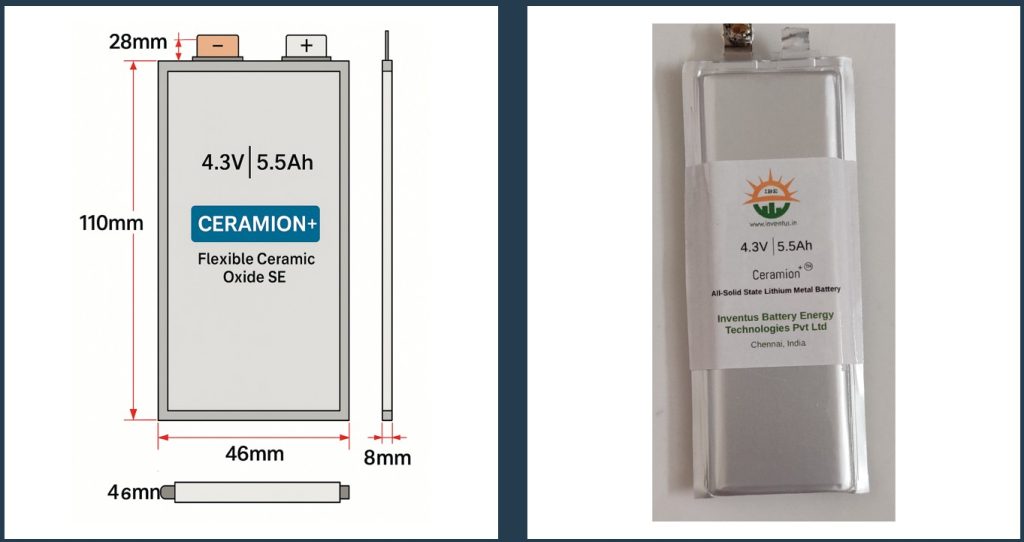

- Stack Uniformity: Scaling pouch cells requires uniform pressure distribution across large formats. Inventus developed advanced calendaring and lamination techniques to ensure even mechanical stability across 46 × 110 mm pouch cells, preventing localized stress points and ensuring reproducible performance.

- Strategic Impact: By overcoming these challenges, Inventus has positioned Ceramion⁺™ as a frontrunner in solid-state manufacturability—combining high ionic conductivity, temperature tolerance (up to 180oC), mechanical flexibility, and scalable processing. These breakthroughs not only advance the science of solid-state batteries but also make them commercially viable for India’s localisation and global deployment.

- Current Performance: Our 5.5Ah pouch prototypes have demonstrated 92.8% capacity retention after 1000 cycles (still counting), under standard operating conditions. This validates the robustness of our stack design and electrolyte formulation.

- Projected Longevity: Based on current degradation trends and interface stability modeling, Inventus projects >6,000 cycles for future commercial cells with NMC811 cathode—especially in EV and stationary storage formats where controlled environments and optimized charging protocols are used.

Your cells currently have an energy density of ~350 Wh/kg. What key elements of your chemistry or stack design enable this performance?

Inventus’s Ceramion⁺™ solid-state battery platform achieves 350 Wh/kg energy density at the cell level, validated through 5.5Ah pouch prototypes. This performance is enabled by a carefully engineered stack architecture built on four key design pillars:

- Lithium Metal Anode: At the heart of our cell is a lithium metal anode with a theoretical specific capacity of 3860 mAh/g, dramatically surpassing conventional graphite anode (10-fold less specific capacity). This unlocks high gravimetric energy potential while reducing anode thickness.

- Thin Ceramion⁺™ Electrolyte Layer: Our proprietary Ceramion⁺™ solid electrolyte is cast into membranes <50 µm thick, offering high ionic conductivity (>4 mS/cm at room temperature) while minimizing inactive mass. This thin, flexible layer is critical for both energy density and manufacturability.

- High-Voltage Cathodes: We integrate NMC811 cathode, enabling charging voltages up to 4.45 V. This high-voltage CAM is stabilized by Ceramion⁺™’s robust interface chemistry, allowing safe operation at elevated potentials.

- Minimal Packaging Overhead: Inventus’s stack design eliminates bulky separators, binders, and liquid reservoirs. Our packaging overhead is as thin as PP/PE separators (25 µm), resulting in a compact, lightweight pouch format with 8 mm total thickness.

In what ways can this technology contribute to the national priority of localisation of advanced cell manufacturing?

- Inventus Battery Energy Technologies is deeply aligned with India’s ambition to localize advanced cell manufacturing and build a resilient domestic battery ecosystem. Our Ceramion⁺™ solid electrolyte and lithium metal all-solid-state battery (LM-ASSB) stack architecture are not imported technologies—they are indigenous IP, conceived, and developed entirely in India by team of Scientists (Dr. S.R.S. Prabaharan, Dr. Siluvai Michael and Dr J. Malathi). This ensures that the intellectual property and know-how remain within the country.

- From a manufacturing readiness perspective, we have rigorously assessed Ceramion⁺™ for compatibility with existing infrastructure. Its flexible ceramic membrane can be processed using roll-to-roll processing techniques on conventional cell winding machines, eliminating the need for costly new equipment. This makes our technology immediately scalable within India’s current gigafactory ecosystem.

- On the supply chain front, Inventus is committed to sourcing and developing materials locally. Our ceramic precursors, lithium salt and other oxides, and cathode active materials (CAM) are integrated into an in-house CAM technology platform, reducing dependence on imports and fostering domestic material innovation.

- Finally, localisation is not just about technology—it is about skills and workforce development. Inventus has designed training modules for solid-state stack assembly, quality control, and safety validation, ensuring that India’s engineers and technicians are equipped to handle next-generation battery manufacturing.

Inventus’s Ceramion⁺™ solid-state battery platform is strategically designed to meet—and exceed—the performance and sustainability benchmarks outlined in India’s PLI scheme for Advanced Chemistry Cell (ACC) manufacturing.

Surpassing PLI Performance Targets

- Energy Density: Inventus delivers 350 Wh/kg at the cell level, exceeding the PLI threshold of 250 Wh/kg

- Cycle Life: Solid-state architecture inherently supports longer cycle life (>10,000) in conjunction with LFP and LFMP cathodes due to dendrite suppression and stable interfaces.

- Safety: Ceramion⁺™ eliminates flammable liquid electrolytes, achieving intrinsic safety under abuse conditions

- Manufacturability: Dry roll-to-roll processing and ambient compatibility reduce CAPEX and enable rapid scale-up

Based on current prototype capabilities, which application segments—EVs, defence, aerospace, or electronics—are best suited for early adoption?

Based on current performance and safety benchmarks, our technology is best suited for:

- Defence: Operates in extreme cold, offers long shelf life, and resists abuse conditions.

- Aerospace: Lightweight, high-energy density, and vibration resilience for satellites, drones and EVTOL.

- Premium EVs: High-voltage tolerance and fast charge potential.

- Consumer Electronics: Mobiles, Laptops, Tablets, Digital Cameras, etc

- Wearables & IoT: Thin form factor and intrinsic safety for compact electronics.

These segments benefit from Ceramion⁺’s unique combination of safety, density, and form factor flexibility.

Where does the technology stand today in terms of maturity or readiness, and what milestones lie ahead before commercial deployment?

Inventus’s Ceramion⁺™ solid-state battery platform has advanced to Technology Readiness Level (TRL) 7/8, reflecting successful high-level prototype demonstrations and validation of manufacturability with Phase 1 funding support from NRDC, DSIR, New Delhi. This positions the technology beyond laboratory proof-of-concept and into the stage of system-level integration and pre-commercial readiness.

Current Status

- 5.5Ah pouch prototypes validated for ionic conductivity, energy density (~350 Wh/kg), cycle life, and safety under abuse conditions

- Stack architecture optimized for roll-to-roll manufacturability and ambient processing

- Internal validations completed; external third-party testing scheduled under NDA frameworks in progress.

Milestones Ahead

- Q1–Q2 2026: Third-party validation with accredited labs and defence agencies

- Q1 2027: Pilot-scale stack assembly line commissioned; A-sample trials begin with OEM partners

- Q4 2027: B-sample trials initiated for EV and aerospace modules, incorporating feedback from A-samples

- Q1 2028: Commercial launch via strategic partners, leveraging licensing, joint ventures, and direct manufacturing for defence/aerospace

What manufacturing or scale-up strategies do you consider essential for making this technology commercially viable?

Commercializing Ceramion⁺™ solid-state batteries requires not just breakthrough chemistry, but a robust and scalable manufacturing model. Inventus has designed a stepwise scale-up strategy that ensures technical feasibility, cost competitiveness, and rapid deployment.

- Modular Pilot Lines: We are soon to establishing modular pilot lines capable of producing stack formats from 5Ah to 20Ah. This modularity allows us to validate performance across multiple applications—ranging from defence and aerospace to premium EVs—while building a clear pathway to gigafactory-scale production.

- Ceramion⁺™ Roll-to-Roll Coating: Our proprietary Ceramion⁺™ electrolyte membranes are engineered for roll-to-roll deposition, enabling high-throughput manufacturing on existing cell winding machines. This compatibility reduces CAPEX requirements and accelerates integration into India’s emerging gigafactory ecosystem.

- Localized Supply Chains: Inventus is committed to local sourcing of lithium salts, ceramic precursors, and cathode active materials (CAMs). By leveraging our in-house CAM technology platform, we reduce dependence on imports, strengthen supply chain resilience, and align with India’s localisation and PLI goals.

- Strategic Partnerships: Scale-up is not a solo journey. Inventus is forging strategic partnerships with OEMs and cell integrators for co-development, pilot deployments, and eventual commercial rollouts. This collaborative model ensures that our technology is validated in real-world systems while accelerating adoption.

Please tell us about any third-party validations your technology has received so far.

- As of now, Inventus’s Ceramion⁺™ solid-state battery technology has undergone rigorous internal validation across multiple performance and safety parameters, including ionic conductivity, cycle life, abuse tolerance, and manufacturability. These internal tests have been benchmarked against global standards to ensure credibility and reproducibility.

- Given that Ceramion⁺™ is a first-of-its-kind technology, we are proceeding cautiously with external handling to protect our intellectual property and ensure safe evaluation protocols. Formal third-party laboratory validations are scheduled to begin shortly under strict non-disclosure agreements (NDAs) with accredited national labs and defence agencies. This phased approach ensures that independent validation is conducted responsibly, without compromising IP security or safety.

Go to market approach – How do you plan to position the technology in the market — through direct manufacturing, partnerships, licensing, or a hybrid approach?

Inventus Battery Energy Technologies is pursuing a hybrid GTM strategy that balances deep-tech control, strategic partnerships, and scalable licensing. Our approach is tailored to the unique demands of solid-state battery commercialization—where safety, manufacturability, and ecosystem integration are paramount.

1. Direct Manufacturing for Strategic Segments

We will retain full-stack manufacturing control for high-value, safety-critical applications such as:

- Defence-grade cells: Where intrinsic safety and low-temperature operability are mission-critical

- Aerospace modules: Lightweight, vibration-resilient stacks for satellites and drones

- Specialty electronics: Thin-form factor cells for wearables, medical devices, and IoT

These segments benefit from Inventus’s proprietary stack design, Ceramion⁺™ electrolyte, and rigorous quality control protocols.

2. Licensing of Ceramion⁺™ and Stack IP

To accelerate adoption and reduce capital intensity, Inventus will license:

- Ceramion⁺™ electrolyte formulations: Including dry processing, coating protocols and precursor sourcing.

- Stack architecture IP: Covering calendaring, lamination, and pressure distribution techniques

- Safety validation protocols: For OEMs and integrators seeking regulatory compliance

Licensing partners will gain access to Inventus’s pilot data, training modules, and process documentation—enabling rapid localization.

3. Joint Ventures and Strategic Partnerships

Inventus is actively pursuing co-development and JV models with:

- Special Purpose Vehicle (SPV) and JV partnerships with Cell Manufacturing OEMs

- EV OEMs: For module integration, BMS compatibility, and vehicle-level validation

- Battery integrators: For scaling pouch formats from 5Ah to 20Ah and beyond

- Government and PSU partners: For pilot deployments under India’s localization and defence mandates

These partnerships will be structured to preserve Inventus’s IP while enabling shared infrastructure and market access.

4. Technology Demonstrators and Pilot Deployments

To build trust and validate performance, Inventus will deploy:

- Pilot-scale demonstrators: 5Ah and 20Ah cells integrated into EV and aerospace platforms

- Field trials: In defence and remote-area applications to showcase thermal resilience

- Investor-ready prototypes: With IRR overlays, cost breakdowns, and scaling projections

These demonstrators will serve as proof points for safety, energy density, and manufacturability.

How does Inventus differentiate itself from global solid-state competitors in terms of scalability, materials, and IP strategy?

Inventus Battery Energy Technologies positions itself as a unique player in the global solid-state race, with clear advantages in scalability, materials innovation, and IP strategy.

Scalability

- Roll-to-Roll Compatibility: Ceramion⁺™ membranes are engineered for deposition on existing cell winding machines, avoiding the need for costly new infrastructure.

- Modular Pilot Lines: Our scale-up model progresses from 5Ah to 20Ah stack formats, enabling rapid validation across defence, aerospace, and EV applications.

- Ambient Processing: Unlike many global peers requiring inert atmospheres, Ceramion⁺™ tolerates ambient conditions, reducing CAPEX and OPEX.

Materials Innovation

- Ceramic–Polymer Hybrid Electrolyte: Ceramion⁺™ blends ceramic oxides with PTFE and dodecane, yielding a flexible, high-conductivity (>4 mS/cm) membrane that solves the brittleness problem of pure ceramics.

- High-Voltage Cathode Compatibility: Supports LNMO, NMC811, and NMC90 cathodes up to 4.45 V, enabling ~350 Wh/kg energy density.

- Localised Supply Chains: Indigenous sourcing of ceramic precursors, lithium salts, and CAMs reduces dependency on imports and aligns with India’s localisation goals.

IP Strategy

- Indigenous IP Development: Ceramion⁺™ and LM-ASSB stack architecture are developed entirely in India, ensuring strategic autonomy.

- India-First Patents: Our IP filings prioritise India’s ecosystem, strengthening national competitiveness while enabling global licensing opportunities.

- Protective Validation Pathway: Third-party validations are phased under strict NDAs, balancing credibility with IP protection.

Additional important feature of ASSB cell technology

Circularity and Recycling Advantages of All-Solid-State Architecture

Inventus’s Ceramion⁺™ -enabled all-solid-state battery (ASSB) platform offers inherent advantages for circularity and end-of-life recycling—addressing one of the most pressing challenges in lithium-ion battery ecosystems.

1. Elimination of Liquid Electrolytes

Traditional lithium-ion batteries rely on flammable, toxic liquid electrolytes that complicate disassembly and pose fire risks during recycling. Ceramion⁺™, being a non-flammable ceramic-polymer solid, allows:

- Dry disassembly without solvent-based neutralization

- Safer handling during shredding and sorting

- Reduced contamination of cathode and anode materials

This simplifies mechanical separation and lowers the cost of recycling infrastructure.

2. Modular Stack Design

Inventus’s pouch cells use a layered, dry electrode architecture with minimal inactive mass. This enables:

- Direct recovery of lithium metal and cathode foils

- Simplified sorting of ceramic electrolyte sheets

- Lower energy input for material separation

The absence of glue, binders, and separators reduces thermal and chemical processing steps.

3. Alignment with India’s Circularity Goals

India’s battery recycling policy emphasizes design-for-recyclability and local material recovery. Inventus contributes by:

- Using indigenous ceramic precursors and lithium salts

- Designing cells for easy mechanical disassembly

- Supporting closed-loop recovery of lithium, nickel, and manganese

Our pilot-scale recycling protocols are being developed in collaboration with academic partners to ensure compliance with India’s Extended Producer Responsibility (EPR) framework.

4. Global Differentiator

Globally, solid-state batteries are often seen as difficult to recycle due to brittle ceramics or exotic materials. Ceramion⁺™ breaks this mold by offering:

- Flexible ceramic matrix (using a dry processing methodology) that withstands mechanical recovery

- Ambient-processable components that reduce energy intensity

- IP-driven stack design that enables traceability and material mapping

This positions Inventus as a leader in circular-ready solid-state innovation, aligned with both sustainability and scalability.

Also read: Government tightens lithium-ion battery black mass export curbs | Stakeholders share perspective

Subscribe & Stay Informed

Subscribe today for free and stay on top of latest developments in EV domain.