Overview of NoPo Nanotechnologies’ carbon nanotube technology and applications

NoPo Nanotechnologies, founded in 2011 and headquartered in Bangalore, India, develops and manufactures single-walled carbon nanotubes (SWCNTs). The company uses a proprietary HiPCO® (High-Pressure Carbon Monoxide) process to produce SWCNTs with diameters in the range of 0.8 to 1 nanometer. These nanotubes are used in applications across electronics, semiconductors, electric vehicle batteries, healthcare, and water filtration.

The company is led by Founder and CEO Gadhadar Reddy, along with Co-founder and CBO Arunima Patel, and Co-founder and COO Anto Godwin, supported by a team focused on advancing nanotechnology solutions.

In a conversation with EVreporter, NoPo Nanotechnologies team shared insights into their proprietary carbon nanotube technology, its applications, and the progress toward commercialization.

Briefly explain your technology for carbon nanotubes.

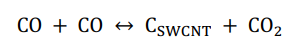

HiPCO® Single Walled Carbon nanotubes (CNTs) are cylindrical molecules made of a layer just 1 atom thick. They exhibit remarkable mechanical, electrical, and thermal properties, making them a revolutionary material in various fields. Our technology involves a proprietary patented reactor developed indigenously. The chemical reaction is called a Reverse Boudouard reaction. Here Carbon Monoxide is broken down into Nanotubes in the presence of a metal catalyst. The Carbon Monoxide required for the process is generated from Carbon Dioxide making it a circular process to sequester Carbon.

The reaction is carried out a high temperature and pressure. The process ensures uniformity and scalability, making it suitable for industrial applications. The tubes produced are 2 lakh times smaller than a hair strand and exhibit incredible material properties.

What are the prospective applications of this technology?

The unique properties of CNTs open up a wide range of applications across multiple industries. Some prospective applications include:

- Electronics: CNTs can be used to create faster, smaller, and more efficient transistors, sensors, and conductive films.

- Materials Science: Enhancing the strength and durability of composite materials for aerospace and automotive industries.

- Energy Storage: Improving the performance of batteries, supercapacitors, and fuel cells.

- Medical Devices: Developing advanced drug delivery systems and diagnostic tools.

- Environmental Applications: Creating efficient water purification systems and air filters.

Please help us understand the role carbon nanotubes can play in lithium-ion batteries.

In lithium-ion batteries, HiPCO® SWCNTs can significantly enhance performance by improving the conductivity and mechanical strength of electrodes. They can facilitate faster electron and ion transport, leading to higher power density and faster charging times. Additionally, CNTs can stabilize the electrode structure, thereby increasing the battery’s lifespan and safety. This is critical in batteries with Silicon Anodes. Silicon increases Anode capacity significantly but suffers from swelling and cracking issues. These are ameliorated by the presence of HiPCO® SWCNT.

What is your technology’s current Technology Readiness Level (TRL)?

Our carbon nanotube technology is currently at TRL 7/8. This means we have successfully demonstrated the technology in a relevant environment and are on the cusp of adopting it with our customers.

What would be the first applications for which this technology can be commercialised?

The first applications for the commercialization of our CNT technology are likely to be in the fields of:

- Electronics: For manufacturing conductive films and sensors. Nanotubes allow for advanced IR Sensors that have implications for military and civilian hardware. It could significantly increase throughput of scientific systems.

- Energy Storage: Enhancing lithium-ion batteries and supercapacitors. Batteries are a major use case for SWCNT and will help improve performance. Nanotubes are now considered an essential ingredient in Batteries.

- Composite Materials: Strengthening materials for automotive and aerospace industries.

Where are you in the process of third-party validation and customer qualification?

We are currently engaged in collaborative projects with leading research institutions and industry partners to validate our technology. These partnerships involve rigorous testing and optimization to meet industry standards. We are in the process of qualifying our technology with potential customers through pilot projects and sample evaluations to ensure it meets their specific needs and requirements.

Also read: Pre-impregnated carbon fiber composite material – The future of automotive manufacturing

Subscribe today for free and stay on top of latest developments in EV domain.