Phase change materials for Lithium-ion battery cooling in electric vehicles

Li-ion batteries have become increasingly popular in electric vehicles in recent years, but their performance is greatly affected by temperature. Extreme heat or cold can result in significant capacity loss and pose safety hazards. High energy density Li-ion batteries generate a substantial amount of heat. It is crucial to dissipate it effectively to ensure battery stability, longevity, and vehicle safety. The implementation of a battery thermal management system (BTMS) plays a vital role in achieving these objectives. The primary aim of a BTMS is to regulate the temperature of the battery cells, thereby enhancing the overall lifespan of the battery system.

This article by Srinivas Burla, Project Manager (Battery and Powertrain) at PURE EV, discusses the types of battery thermal management systems and the advantages of using phase change materials for battery cooling.

Types of Battery Thermal Management System

Various techniques are utilized in a BTMS, including the use of extended surfaces, immersion cooling, cold plates, thermoelectric coolers, phase change materials, and silicon pads and potting materials. BTMS can be categorized into two main types:

Active Methods: These methods rely on external power sources to facilitate their operation. They incorporate built-in mechanisms for heating and/or cooling.

Passive Methods: Passive BTMS do not require any external power supply for its operation. It uses the ambient environment to dissipate the heat. As they do not need any external power source, they are the most sought methods in the field of developing a thermal management system. These methods also have the advantages of being compact, less complex, safe, cost-efficient and enhanced life cycles.

Using Phase Change Materials (PCM) for thermal management

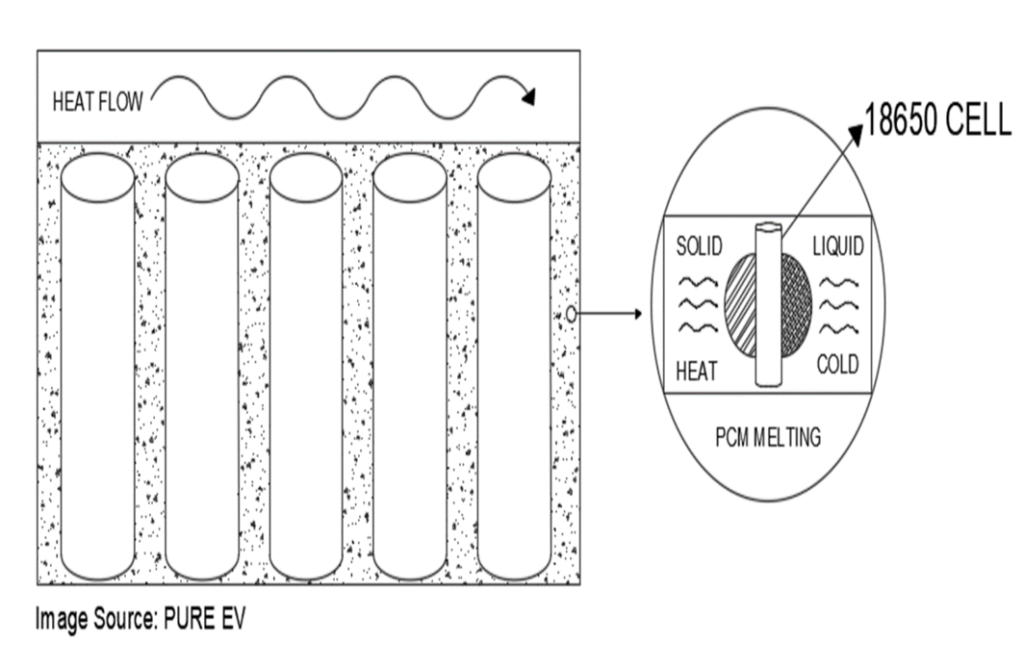

PCMs or Phase Change Materials could absorb a large amount of heat without excessive changes in temperature during the solid–liquid phase change. Passive thermal management systems can control the battery temperature uniformly within the phase change temperature, even without consuming any extra energy. The parameters to consider when using phase change materials in a battery pack are as follows:

Thermal Conductivity: High thermal conductivity allows for better heat dissipation and distribution, facilitating the transfer of heat away from the battery cells.

Melting Temperature: The melting temperature range aligns with the desired operating temperature range of the battery pack. It absorbs heat from the battery when it exceeds its melting temperature and releases heat when it solidifies.

Latent Heat: The high latent heat of fusion is the amount of energy absorbed or released during the phase change process. High latent heat allows the PCM to absorb or release more heat energy, thereby effectively controlling the battery pack’s temperature.

Cycle Stability: The PCM should be stable over multiple heating and cooling cycles to ensure long-term reliability. It should be able to undergo repeated phase transitions without any significant degradation or changes in its thermal properties.

Compatibility: The PCM should be chemically compatible with the battery pack components and materials to avoid any adverse reactions or performance issues. It should not cause corrosion or degradation of the battery cells or other components.

Density: Higher density stores more heat in a given volume, which is beneficial in applications where space is limited.

Types of Phase Change Materials (PCM)

Phase change materials can be categorized into various classes, and among them, paraffin waxes are widely used for thermal management in electronics. These waxes possess several advantageous properties, such as a high heat of fusion relative to their weight, a wide range of melting points to choose from, reliable cycling capabilities, non-corrosiveness, and chemical inertness. They are compatible with most metals, making them a suitable choice. Another notable feature is their ability to store a significant amount of latent heat, and they are available across a broad temperature spectrum.

PCM types include paraffin waxes, Non-Paraffin organics, hydrated salts, and metallics.

Source: https://www.1-act.com/products/pcm-heat-sinks/pcmselection/

PURE EV is using advanced packaging materials that are critical to avoiding thermal runaway scenarios for lithium-ion batteries, which could turn into catastrophic events.

About the author:

Srinivas Burla

Company Name: PURE EV

Designation: Project Manager (Battery and Powertrain)

Also Read: Lithium-ion battery manufacturing in India – current scenario

Subscribe today for free and stay on top of latest developments in EV domain.

Pingback: A dialogue on advanced Lithium-ion battery inspection and analysis • EVreporter

after absorbing heat from cells how PCM will be cool down(solidify)in closed chamber