Facilitating sustainable electrode production for Lithium-ion cells | Dr Hannes Schmüser, Dürr Systems AG

At the recently concluded Battery Show India 2023, Dr Hannes Schmüser, President & CEO – Division Clean Technology Systems of Dürr Systems AG, made a presentation on the topic of “Driving Sustainability in Lithium-Ion Battery Electrode Production“.

Team EVreporter caught up with him to understand more about Dürr solutions for electrode production and how these solutions can help Lithium-ion cell manufacturing companies. Here are some excerpts from that interaction.

How does Dürr help lithium-ion cell manufacturers set up their production facilities?

Dürr has been a reputable supplier of automotive production facilities for many decades and has extensive project management expertise to prove it. We can observe from the market that establishing a lithium-ion cell manufacturing facility requires strong project management, including aligned interfaces, site & construction management, and ramp-up management, among others. Fortunately, we can leverage our experience and in-house competence, which adhere to the high automotive standards, to set up battery giga-factories. Additionally, we have partnered with the German mechanical engineering firms Grob and Manz, enabling us to cover almost 90% of the entire battery cell manufacturing value chain. With this collaboration, we can deliver complete production lines with aligned project management, interfaces, and comprehensive system integration.

What are the key challenges and considerations when setting up coating and drying equipment for electrodes?

Setting up electrode coating lines is a complex process that requires efficient management. It involves more than just installing equipment on-site; people must be trained, and environmental factors must be considered to ensure a seamless production start and ramp-up. Understanding the coating and drying process in detail is crucial to being proactive instead of reactive and anticipating potential problems before they occur.

What are the critical factors that cell manufacturers should consider when selecting and installing electrode coating and drying equipment?

When choosing equipment for electrode production, it is important to consider the expertise required for both the coating and drying processes, which involves dealing with harmful solvents that must be processed and filtered in accordance with local regulations. At Dürr, we offer comprehensive solutions for electrode production that ensure seamless integration of technologies and interfaces. We don’t just install equipment and leave; we provide training and service to ensure smooth production start-up. Our turnkey approach enables us to deliver true customer benefits, including processes that are designed to fit together perfectly.

How do Dürr solutions help improve the efficiency of electrode coating and drying processes?

Battery cell production heavily relies on raw materials, which are a major cost driver. Unfortunately, electrode production is known to have low yield rates compared to other process steps in the value chain. This is a significant pain point for the industry. At Dürr, we have taken proactive steps to address this issue by designing equipment that is highly efficient and effective. Our machinery is equipped with inline quality measurement tools and AI-powered systems that collect and analyze real-time data. This allows us to offer closed-loop control systems that significantly reduce scrap rates, improve overall performance, and increase efficiency.

Middle: Mr Swapnil Dixit, Head – Clean Technology Systems of Dürr India Private Ltd.

Right: Dr. Hannes Schmüser, President & CEO – Division Clean Technology Systems of Dürr Systems AG

How does Dürr address sustainability concerns associated with electrode manufacturing?

Lithium-ion batteries are made from materials that can be harmful to the environment. Additionally, the process of manufacturing cells, especially producing electrodes, is known to be energy-intensive.

To address these concerns, we have implemented closed-loop controls and inline quality measurements, which have significantly reduced scrap rates and energy consumption. Our drying ovens can also be designed to use electrical energy, which helps to reduce exhaust gases. We are proud to be the world market leader in air pollution control and solvent recovery systems.

Our system achieves a 99.8% solvent recovery rate, which helps to protect the environment by preventing harmful pollutants from being released into the air. Furthermore, the recovered solvents can be distilled to achieve an electronic grade purity with a 95% reuse of the solvents in the process, leading to significant cost savings.

What trends do you see in the evolving technology for electrode manufacturing?

There are two main focus topics for Dürr. The first one is to develop sustainable and alternative drying technologies further. In particular, Dürr sees huge potential in the laser drying of wet-coated electrodes. By using laser drying, it is possible to achieve high energy densities and heating rates, resulting in a greatly improved energy efficiency. Additionally, the process can be controlled very quickly.

However, the main trend is the development of technologies for dry coating. Initial lab and pilot productions have proven that this technology works. The challenge is to scale up these technologies and the respective equipment for mass production. Dürr is taking big steps in this direction, so stay tuned.

Is Dürr equipment designed to work with material requirements of different types of cathode and anodes?

Certainly, every customer has unique requirements, materials, and their corresponding composition. Our equipment is compatible with all commonly used anode and cathode materials. In case a customer needs special or new materials that are not yet available in the market, we work together with customers in a joint approach to provide customized solutions to fulfil their requirements.

Can you discuss the scalability of your equipment – if it can be adapted for both small-scale and large-scale facilities?

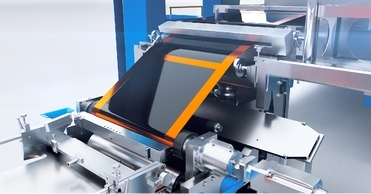

Our products are designed to be highly adaptable and expandable. We offer solutions that range from lab and pilot lines to large-scale giga-factory production equipment. Our state-of-the-art tandem coating technology provides a robust and mature option for both series and large-scale production. Additionally, Dürr provides dual-side coating for lab and pilot lines, which allows both sides of the foil to be coated simultaneously, reducing the need for multiple drying.

What kind of support and training does Dürr offer to manufacturers who go with your equipment?

Providing support and training is essential to enable customers to fully utilize the potential of our equipment and machines. At Dürr, we consider our customers as partners right from the start. Our top engineers work closely with them to find the perfect solution for their specific requirements. We provide the appropriate support for every stage of the project, from the initial idea to factory planning and SOP. With our vast global network, we offer 24/7 local support and training services wherever necessary and right from the start and ramp-up of the facility. We are fully committed to the success of our customers and do not consider projects complete until our customers are 100% satisfied.

Are there any recent case studies of your solution implementation that you can share with us?

We are not authorized to reveal the names of our customers or projects due to non-disclosure agreements. Nonetheless, we have been providing coating solutions in the market for many years and have a broad installation base. The market is continuously evolving and highly dynamic. Due to the shift towards e-mobility, we are in close contact with all major OEMs, tier 1 and tier 2, and start-up companies. Additionally, we are thrilled to announce that we have won our first joint OEM project with Grob and Manz, which is currently in implementation.

Also Read: India’s lithium-ion cell supply chain- leading players and plans

Subscribe & Stay Informed

Subscribe today for free and stay on top of latest developments in EV domain.