BESS Plant Setup – Part 4

Technology for BESS Manufacturing

This article is a follow-up to the BESS Plant Setup Series, published on EVreporter in June, July, and August 2025 editions by Rahul. While Part 3 focused on the equipment requirement for BESS manufacturing, Part 4 focuses on the technology for BESS manufacturing.

BESS manufacturing technology must include the following to avoid failures:

- Good understanding of the cell characteristics and imposing mandatory capacity grading if the cell production date has passed beyond a certain limit.

- Using cells with uniform parameters when making the module, pack and cluster. It includes a good understanding of the sorting parameters of the cells.

- Knowledge of equipment operation to produce battery modules and battery packs, with strict quality checks at every step and end-of-line testing. The details about the required equipment were discussed in detail in Part 3 of this series.

- Know-how of integrating the Battery Monitoring Unit (BMU) with cells and setting the right parameters. BMU monitors basic parameters of the battery pack, such as voltage & temperature.

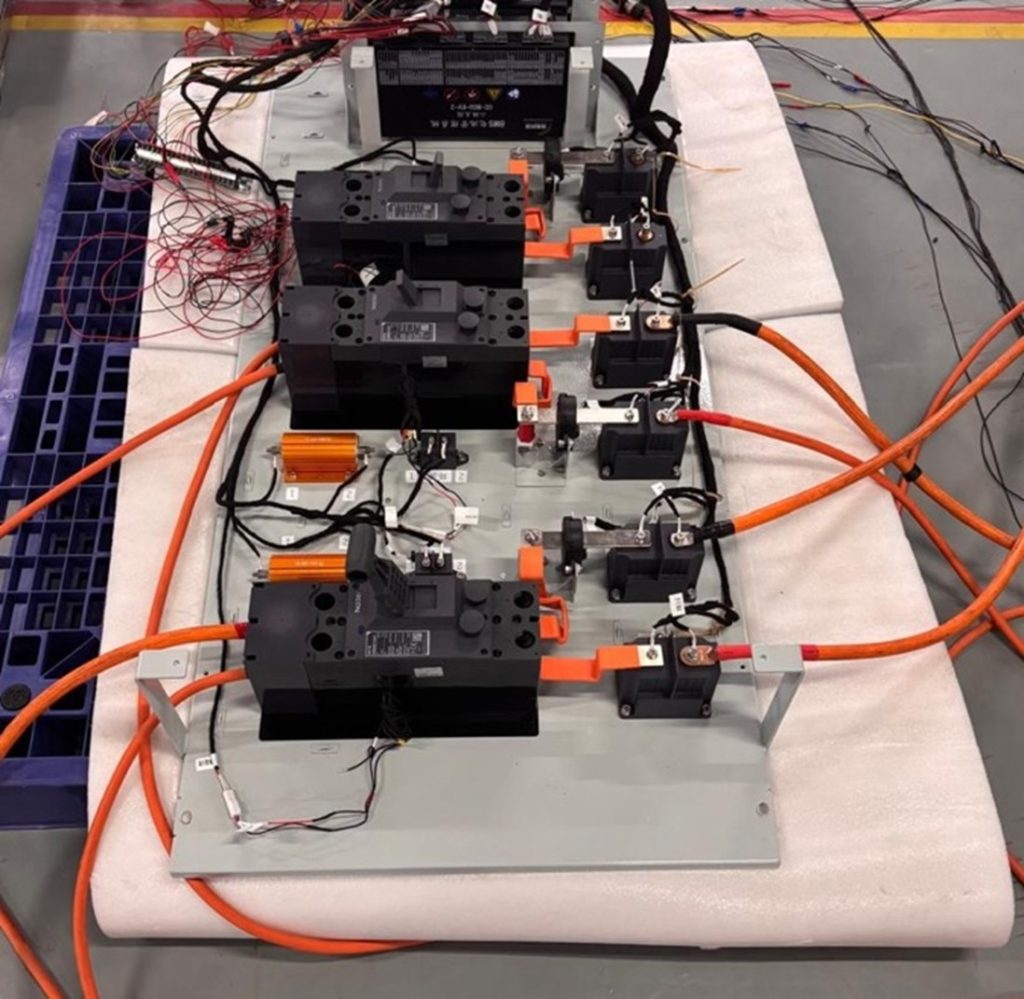

High Voltage Box Inside used for 104S Packs

- Know-how of integrating battery packs in series along a high voltage (HV) box to form a cluster. It includes electrical, mechanical and communication integration along with the HV box. An HV box consists of a string/cluster BMS, fuses, relays, and other components, which must be used with the required parameters. String/cluster BMS collects data from all its related BMUs, calculates SoC, SoH, and other metrics, and sends commands to the BMUs.

- The configuration for the HV box varies depending on the type of application. For example, an HV box used in a commercial and industrial application battery cluster would function until 1000VDC, and an HV box used in a grid-utility scale application battery cluster would function until 1500VDC and sometimes slightly more if the charging voltage per cell is 3.65V.

- Know-how of integrating multiple clusters with the main BMS of the complete battery system while building a multi-cluster-based energy storage system. In such a system, clusters are connected in parallel to maintain the same voltage and increase the current output. The main BMS communicates with all the cluster BMS inside the container and also with its related PCS and EMS.

- The DC combiner box is used to combine the DC power coming from each cluster into a single DC output. Similarly, an AC combiner box is used to combine AC power coming from multiple PCS, popularly used in commercial and industrial applications using multiple string PCS. String PCS for grid-utility scale is gaining popularity for long-duration projects such as 6-hour and 8- hour projects.

- Knowledge of designing pathways for air cooling or liquid cooling medium inflow and outflow at the pack level and at the battery system container level. Bad design can choke up the heat towards the end of the battery pack, from where the outflow happens, and can degrade cells faster at that place.

- Know-how of mechanical components design, such as for battery pack enclosure, metal racks for holding battery packs and other components and battery system container to accommodate all the required components in a protected manner. For projects with high humidity or salinity exposure, battery system containers must use corrosion paint.

- In case of using 20ft High Cube ISO container for grid-utility projects, the container used must ensure that it can carry the total weight of the battery system since the battery system weight is higher than the normal shipping container capability.

- Know-how of electrical integration for busbars and cable integration for cells, packs and clusters. The right size must be ensured after considering the temperature derating of the conductor materials.

- Know-how of integrating communication protocols between the main BMS, PCS, and EMS, and power integration between the DC system and PCS, and running debugging tests to diagnose any issues. This is the most complicated and time-consuming part of BESS manufacturing, and around that time, the customer comes to carry out pre-shipment FAT (factory acceptance test).

- If shipping a fully assembled battery system by trucks, the trucks must have the capability to carry the weight of the container since the trending model of 5MWh BESS containers used for grid-utility scale projects weigh between 43 and 44 tonnes. Cranes for lifting such containers must be deployed at the BESS manufacturing facility to lift the BESS container and place it on a truck.

This article was first published in EVreporter September 2025 magazine.

In Part 5, I will discuss understanding the parameters of FAT (Factory Acceptance Test).

About the author

Rahul Bollini, Bollini Energy

Rahul is an R&D expert in Lithium-ion cells with 10 years of experience. He founded Bollini Energy to assist in deep understanding of the characteristics of Lithium-ion cells to EV, BESS, BMS and battery data analytics companies across the globe. Contact | +91-7204957389; bollinienergy@gmail.com.

Also read: Understanding battery energy storage system (BESS) | Part 7 – Project implementation planning

Subscribe today for free and stay on top of latest developments in EV domain.