BESS Plant Setup – Part 5 | Factory Acceptance Test

Factory Acceptance Test (FAT)

This article is a follow-up to the BESS Plant Setup Series, published in the June, July, August, and September 2025 editions by Rahul. While Part 4 focused on technology for BESS manufacturing, Part 5 focuses on understanding the parameters of the Factory Acceptance Test (FAT).

FAT is the time when the buyer comes to check that they are receiving what they had ordered before making the final payment. It is an important step in the project, where both parties understand that they are on the same page, which enables a successful project.

FAT inspection from BESS manufacturer needs to cover the below parameters:

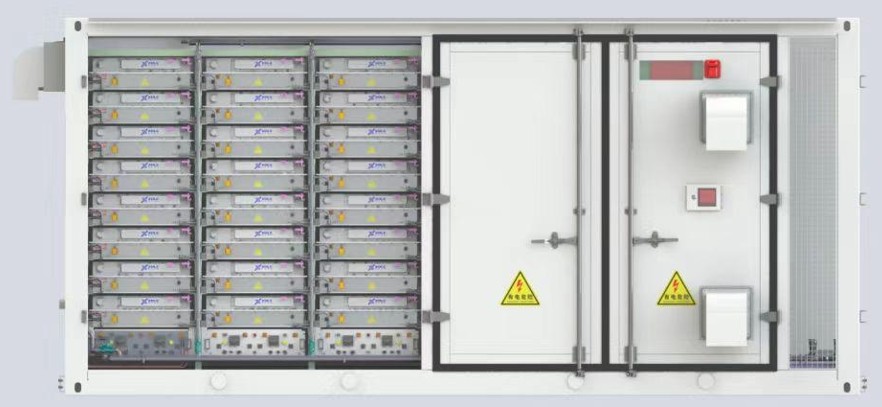

- Visual inspection of the BESS container for uniform paint job, cracks, dents, rusting, burrs and sealant in the gaps of doors and windows.

- Visual inspection of the battery rack structure and battery packs for cracks, dents, and rust, and ensuring the surface is smooth and clean.

- The battery pack and high-voltage (HV) box fuse sizing are appropriate.

- Visual inspection of labels and logos to ensure correct font type, size and colour scheme.

- Cable checks if they are routed smoothly without wires being exposed. Check that wires and circuit breakers are connected properly and that the wires are not loose.

- The crimping terminal should not have any deformity, and the cable insulation should be intact without any tears. The internal wiring is done correctly, and there is no short circuit. Each cable’s conductivity meets the power requirement.

- DC insulation test value for a specific time is conducted between the positive terminal and ground, and between the negative terminal and ground. It must be higher than the specified value. It is conducted at a DC voltage higher than the battery’s maximum DC voltage capability.

- BMS parameters are displayed as required, the live status of each battery cluster is displayed, and the alarm interface shows no pending alarms. BMS settings are correct, and communication between each level of BMS is normal.

- The cell voltage difference, maximum voltage, and minimum voltage between all cells must not exceed a specified value.

- Opening any cluster door triggers provides an alert on the controls interface.

- Checking if the emergency stop button works, BMS disconnects all DC contactors, and emergency stop information is displayed on the controls screen. Also check if the contactor responds well to the normal commands.

- Working light indicators on the high voltage box, as well as in the electrical room.

- Verifying that the 3-phase power connected outside the electrical room starts the UPS.

- There is no leakage in the liquid cooling pipe system, and the cooling and heating functions of the liquid cooling unit are normal. HVAC has no obstructions to airflow.

- The fire protection system is functional, and the alarm functions are visible on the control screen. Sensors for temperature, humidity and smoke are functional.

- View the dehumidifier value displayed, change its value to a lower value, and check if the humidity changes as per the required value in a short period of time.

Image of BESS 20 ft Container (4 door model)

FAT documentation from BESS manufacturer needs to include the following:

The FAT checklist document is prepared in accordance with the above parameters and is used to verify each point.

- Data from BESS datasheet and Battery-related certification documents are checked and verified.

- Shipping certifications are checked and verified, and a discussion with the shipping company is initiated, as most companies provide a quotation only up to FOB.

- Fire protection system design document.

- Auxiliary power consumption document.

- Basic civil structure design along with hoisting details.

- Power distribution diagram and single-line diagram of the BESS.

- Suggestions for BESS placement/arrangement on site during deployment.

- BESS user, installation and operation manual.

- Degradation data from FAT to SAT, and it is what the storage/shipping conditions are.

- Warranty documents must be reviewed to ensure they align with the project requirements. This is a crucial aspect of the project, and I will elaborate on it in detail in Part 6 of this series.

- Documentation for extended warranty terms after the standard warranty.

- Review long-term service agreement (LTSA) to suit the project requirement in terms of maintenance schedule. I will also be writing about it in detail in Part 6 of this series.

This article was first published in EVreporter October 2025 magazine.

In part 6 of this series, I will write about understanding the warranty terms and LTSA for BESS.

About the author

Rahul Bollini, Bollini Energy

Rahul is an R&D expert in Lithium-ion cells with 10 years of experience. He founded Bollini Energy to assist in deep understanding of the characteristics of Lithium-ion cells to EV, BESS, BMS and battery data analytics companies across the globe. Contact | +91-7204957389; bollinienergy@gmail.com.

Also read: BESS Plant Setup – Part 4

Subscribe & Stay Informed

Subscribe today for free and stay on top of latest developments in EV domain.