How parts other than the powertrain impact EV performance

This article was first published in EVreporter August 2021 magazine.

The global automotive industry is undergoing a powertrain technology transformation from ICE to EVs. Even though some leading automotive OEMs have launched EV variants in the market, in many cases, the vehicle itself is a mere replacement of the powertrain from ICE to EV while other specifications remain more or less the same as ICE vehicles.

Dr Maruti Khaire (Head EV and Special Projects at SKF India) discusses the vehicle subsystems apart from the powertrain that need a focussed design approach to get optimum performance from an electric vehicle.

Introduction

Automobile vehicle design is a complex field involving many parameters and their interactions, including occupant comfort, space, vehicle’s operational performance in varying load conditions, vehicle’s responsiveness to different terrains, the safety of vehicle system and the occupants, and in current times connectivity, entertainment and myriad other aspects. Even though these parameters apply to both the ICE vehicles and the EVs, the underlying dynamics differ. The application of the vehicle design principles may be the same for both powertrains, but the acceptance criteria will have some exclusivity between the two.

Some critical parameters may be compromised when ICE vehicles are converted into EVs, which can be appropriately addressed when designing an electric vehicle from scratch.

EV design discussion typically focuses on the motor+controller, battery, battery management system and their performance improvement. However, other vehicle systems which could also contribute to EV optimization are generally less discussed or carried over from the ICE vehicle experience.

This article focuses on vehicle subsystems like bearings, vehicle chassis, wheel ends, tires, etc., which are critical to an EV’s performance but find little mention in the EV discussion.

Technical Background

Some technical background is important to understand the significance and impact of various sub-systems and their design consideration on overall EV performance.

Vehicle Power to Weight Ratio

Defined as the ratio between the rated motor power and vehicle kerb weight. The vehicle should have the right balance of power and kerb weight to achieve the desired road performance. A heavier vehicle requires a higher power motor and demands more energy from the battery to achieve the desired range, speed, and acceleration.

Vehicle Energy Consumption Parameters

The powertrain’s energy demand varies based on total road loads experienced by the vehicle during operation. Vehicle total force magnitude is dynamic and based on the operating conditions.

F (total) = F (inertia) + F (inclination) + F (road) + F (aerodynamic)

F inertia – a function of vehicle weight and acceleration.

F inclination – a function of vehicle weight and road surface inclination.

F road – a function of vehicle weight, road inclination, road rolling resistance coefficient.

F aerodynamic – a function of the frontal areas of the vehicle and speed of the vehicle.

The above parameters take comparatively higher significance for EVs as the energy storage is limited and recharging the battery takes longer. Optimization of these parameters can influence the vehicle’s operating range [distance/charge] for a set battery capacity. Increasing the battery capacity adds to the overall cost and vehicle weight.

Energy Consumption Pattern

During acceleration and normal running conditions, the vehicle’s energy consumption increases with time, whereas, during braking, energy consumption reduces with time.

Basically, weight, speed, friction, and heat are the key parameters that must be optimised to achieve the intended vehicle performance.

EV System and Subsystem Considerations

In this section, we will discuss various subsystems and systems that are commonly not discussed during the EV powertrain discussion; however, they can significantly influence EVs’ performance.

Vehicle Body and Chassis

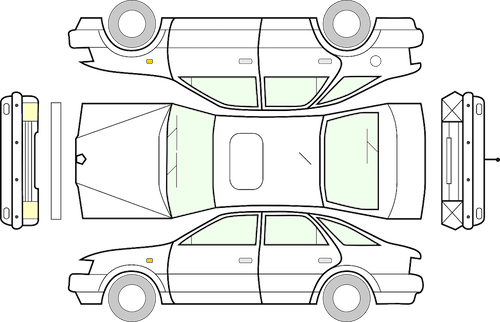

In the automobile context, vehicle body and chassis terms are sometimes used interchangeably. However, both have different functions and influences on vehicle operation.

Vehicle Body – An assembly of components that form the structure which supports the vehicle (frame), accommodates and protects vehicle occupants. The body acts as the vehicle’s visible skin and provides it with a unique appearance.

The vehicle body influences the inertial force as well as the aerodynamic force – both of which impact the energy consumption of the powertrain.

Aerodynamic forces are proportional to body frontal surface area and square to the vehicle speed.

Therefore, based on the vehicle’s type and speed considerations, the body shape is formed to achieve the lighter / optimum weight and the lowest possible aerodynamic forces. An EV powertrain has lower noise and vibration; so the materials or parts typically used to absorb the noise and vibration in an ICE vehicle are not required. Body re-engineering is possible by using lighter materials.

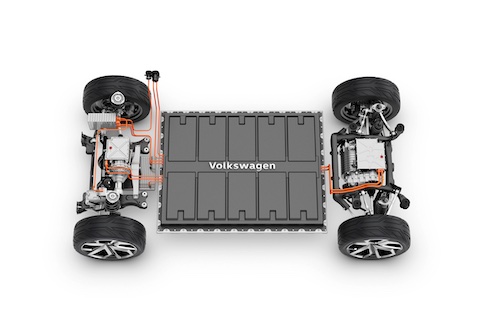

Vehicle Chassis – Typically, the chassis is the structure located underneath the vehicle. It supports the vehicle body, powertrain, battery, and other aggregates. The chassis also supports the wheels and suspension system of the vehicle, influences vehicle dynamics, safety, NVH, ride and handling. The vehicle chassis is a “connection” of the vehicle to a series of systems and subsystems which define its internal structure.

Chassis design and components are critical to vehicle rigidity, strength, durability, safety, wheel motion control, ride feedback and vehicle handling. In EVs, chassis can perform functions such as providing safety to ensure the lowest possible impact in case of collision, light-weighting to reduce vehicle energy consumption, good vehicle manoeuvrability and comfort to achieve a silent operation in and outside the vehicle.

In an EV, safety has dual facets – the safety of occupants and the safety of the electrical system including the battery. Excellent protection of electrical components is essential to avoid catastrophic damage.

The chassis and body of the vehicle influence vehicle weight, aerodynamic forces and vehicle overall stability. If the body and chassis are optimized based on the powertrain, it will add significant value to vehicle energy consumption, safer operation, and overall life of the vehicle.

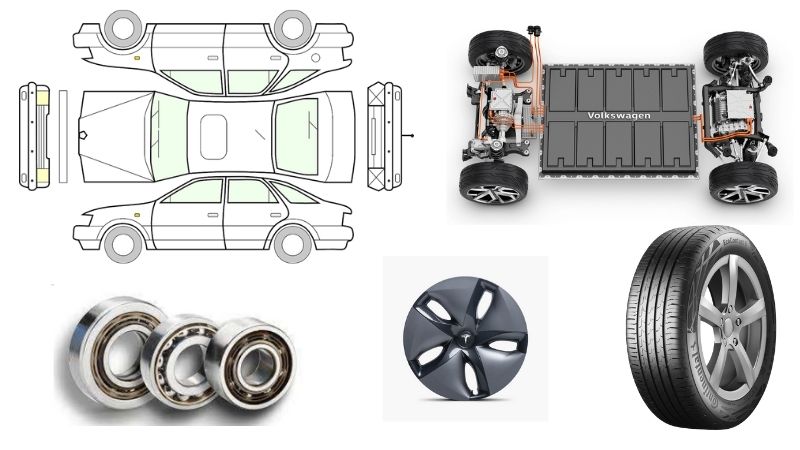

Bearings

Typically, bearings are a part of major aggregates like motor, transmission, wheel, steering and other systems in an EV. Even though they are buried deep within a vehicle system, they are critical to drivetrain efficiencies and reliability of the automotive systems. As the automotive industry transforms from ICE to EVs, it impacts the way bearings are designed and deployed.

Modern powertrains have additional requirements from bearings considering constraints like lower weight, space, and demanding operating conditions, including higher temperatures, speeds, inability to lubricate, and longer service intervals or no service for the design life of the system. In modern EV powertrains, bearings are implemented not only for primary functions, i.e. supporting the load and reducing the friction but also for multiple other integrated functions like signal transmitting devices on the motor, rotor positioning sensing, speed sensing and vehicle health monitoring systems.

Modern EV motors run at higher speeds for efficient motor operations, and bearings need to be optimised accordingly. Bearings operating at higher speeds also need to operate silently, with less vibration and at lower temperatures. So, in addition to standard bearings, modern EVs also implement hybrid bearings, which are lightweight and have higher stiffness “ceramic” rolling elements.

Bearings can act as a catapult to reduce the overall system size and weight. Power dense bearings can carry more load per unit size. As the size of the bearing reduces, so does the size and weight of the interfacing enclosure and surrounding components. Bearings also help improve the vehicle ride and handling by providing the required stiffness to the system. Bearings also impact the NVH of the aggregate system and facilitate friction reduction, which results in energy saving.

Bearings play a critical role in EV powertrain, wheels, and other systems to reduce energy consumption, enhance vehicle reliability, and reduce complexity by implementing additional functionality. Bearings play a vital role in system size and weight reduction and facilitate lower friction.

Wheel

Wheel and tire together have a significant influence on the EV energy consumption and improvement of driving range. A bigger wheel size will have an adverse impact on the vehicle efficiency and the range of the EV. A mindful wheel design will play a significant role in the efficiency improvement of the EV powertrain.

A study conducted on Tesla vehicles by Car and Driver revealed that aero wheel covers on Model 3 enhanced efficiency by 3.4% and added up to 10 miles of range per charge.

It is important to note that wheel design also includes the wheel bearing design and its packaging. Conventional taper roller bearing design can add friction to the system and will result in higher energy consumption. However, Hub 3 design uses multiple rows ball rolling element design, which can lower friction and improve vehicle efficiency. Additionally, integrated wheel bearing design simplifies the assembly, enhances the stiffness, reduces the weight, and can provide better reliability and ride handling.

In modern cars and two-wheelers, in-wheel motor implementation is also observed. Each wheel can have its own in-wheel motor, which is controlled via a central control module. This construction can have good accelerator responsiveness as well as the behaviour of the car more aligned with the steering by independently controlling the left and right wheels. In-wheel motors, in the case of two-wheelers, simplify the drive system significantly and reduce the overall weight and cost of the vehicles. However, in-wheel motor construction also requires special attention to sealing the system to avoid malfunctions due to road undulations.

Tires

Tires have a significant role to play in improving the efficiency of the EV powertrain. EVs should consider tires with a “tall and narrow” shape to reduce rolling resistance, which helps increase efficiency. Generally, wider tires have excellent handling as greater width means a larger contact area and better road grip. However, this greater contact area also adds to friction and results in a loss of energy. Energy efficiency is all the more critical in the case of EVs due to battery cost as well as recharging time. Therefore, EV tire selection should balance the road grip and energy consumption.

Tire for electric car | Continental

– The tire tread pattern and tread rubber compound need to be designed to handle the rapid torque response of the electric powertrain. Tire treads also influence the quiet running of the vehicle and running noise inside the body.

– Tires with a high load-bearing capacity should be considered to handle the extra weight of the battery effectively.

– Recent research conducted by Toyota and Michelin tires revealed that airless tires are effective for EVs.

– Tire wear and its dust also need to be considered. Lower tire wear means lower emission.

Brakes

Braking converts a vehicle’s kinetic energy into thermal energy (heat). In modern EVs, regenerative brakes are implemented to conserve this energy and store it back to the battery. Regenerative braking not only reduces the wear/tear of the brakes but also enhances the driving range. Brake pad wear dust is also another consideration to make the vehicles emission-free.

Subscribe & Stay Informed

Subscribe today for free and stay on top of latest developments in EV domain.

Thank you Priyakshi and team EVReporter.com for your encouragement to make this article happen. I appreciate your support and continued effort to ensure the article reaches to a larger audience. Keep up the good work !!

Great article..looking forward for more informative articles from you..great job guys