RCPL secures patent for Quasi-solid-state Magnesium-ion battery and method of fabrication

A recently granted patent (479386; PCT: PCT/IN2023/050551) highlights a development by Chennai-based Ramcharan Company Pvt Limited (RCPL) in the field of Quasi-Solid-State Magnesium Ion Batteries (QSSMgBs) and the associated fabrication method.

The ongoing demand for energy storage solutions, coupled with the rising costs of traditional raw materials like Nickel (Ni) and Cobalt (Co), has prompted the exploration of alternative battery technologies based on earth-abundant materials such as sodium, potassium, calcium, magnesium, aluminium, and zinc.

About Mg-ion batteries (MBs) – MBs have gained attention due to the advantages of magnesium, including its high theoretical specific capacity and abundance, making it an economically favourable option compared to lithium. Magnesium is approximately 30 times cheaper than Lithium and 5th abundant metal in the earth’s crust.

The major advantages of Mg over Li comes from the following:

– Mg metal anodes possesses higher volumetric capacity of 3833 mAh cm-3 in comparison to 2036 mAh cm-3 for Li

– Low susceptibility towards dendrite formation by Mg2+, which is very high in Li metal anodes

– Less reactivity and higher mechanical strength of Mg metal anode allow it to be prepared at room temperature and in atmospheric conditions when compared to the high reactivity of Li metal in air, moisture and environment, and hence Mg is easy to produce on a large scale.

However, challenges in the commercialization of MBs arise from electrolytes reacting with the Mg metal anode, leading to the formation of insulating passivation films on Mg anode surface that hinders the diffusion of Mg2+ ions during charge-discharge cycle and subsequent solid state electrodic reactions.

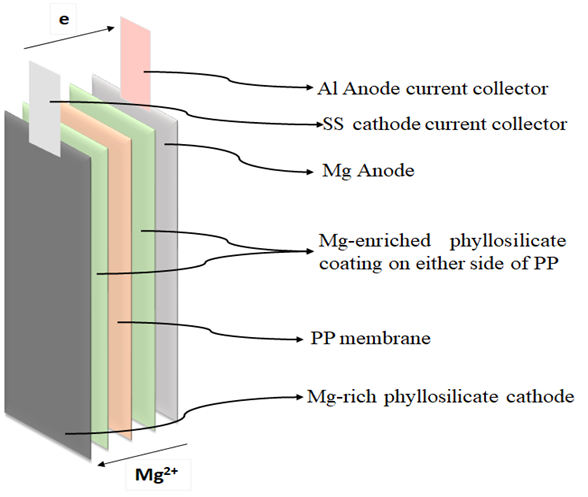

Ramcharan Company said that its invention addresses the above challenges by fabricating QSSMgBs using highly porous phyllosilicates naturally rich in magnesium (Mg) or iron (Fe) as cathode, phyllosilicates enriched with Mg as QSSE, Carbon Black (CB) or Graphite or Mg metal as anode.

Performance claim – 85% capacity retention after 1000 cycles and a high energy density and specific capacity of ≥800 Wh/kg and ≥350 mAh/g, respectively.

Compared to liquid electrolytes, QSSEs offer inherent advantages such as:

1. Self-supporting, highly non-volatile, thermally stable, and safe

2. Their flexibility reduces electrolyte leakage

3. Mg reactivity with electrolyte to passivate Mg with high ionic conductivity of the order of 2.87 mS/cm, which is at par or higher than that of conventional liquid electrolytes

4. The use of Mg-rich phyllosilicate as a cathode enhances dynamic properties and cycling stability, significantly improving the electrochemical performance of QSSMgBs

Kaushik Palicha, Director, Ramcharan Company Private Limited, said that RCPL’s QSSMgBs are distinguished by their use of environmentally friendly, earth-abundant Mg-enriched phyllosilicates as QSSE, contributing to a flexible, recyclable, and fast electrode kinetics-based design. The flexibility of QSSMgBs allows customization for various form factors, making them suitable for applications ranging from low-power electronics to e-mobility to stationary storage.

What is the relevance of this patent/technology?

This technology’s relevance lies in the utilization of earth-abundant materials, contributing to next-generation batteries, ensuring supply chain sustainability, promoting indigenization, and offering high energy density of the order of 0.89kWh/kg, high specific capacity at the PoC stage of 700 mAh/g, high cycle stability and no or negligible self-discharge.

TRL of this technology

The technology is currently at Technology Readiness Level 5, with ongoing efforts towards commercial stabilization. RCPL aims to achieve a TRL 9 product by the end of March 2024.

What are the potential areas of immediate application?

On scale, the technology will cater to e-mobility, stationary storage, and electronic applications.

What is the path to market launch/commercialisation, and how will this technology be deployed on target applications?

For automotive applications, we are in the process of scaling up prototypes to test in e-vehicles. Collaborations are underway with Indian automotive industries and the Indian space sector to bring this technology to market.-

Time required for commercialisation

End of 2024

Entities you are working with to help bring this technology to market?

Companies from the Indian automotive industry and Indian space sector.

Also read: Understanding Lithium-ion batteries| A long read

Subscribe & Stay Informed

Subscribe today for free and stay on top of latest developments in EV domain.

Pingback: RCPL secures patent for Mg-battery with a solid electrolyte | Targets commercialisation in early 2025 • EVreporter